Hydraulic Toggle Mining Ball Mill Equment

.jpg)

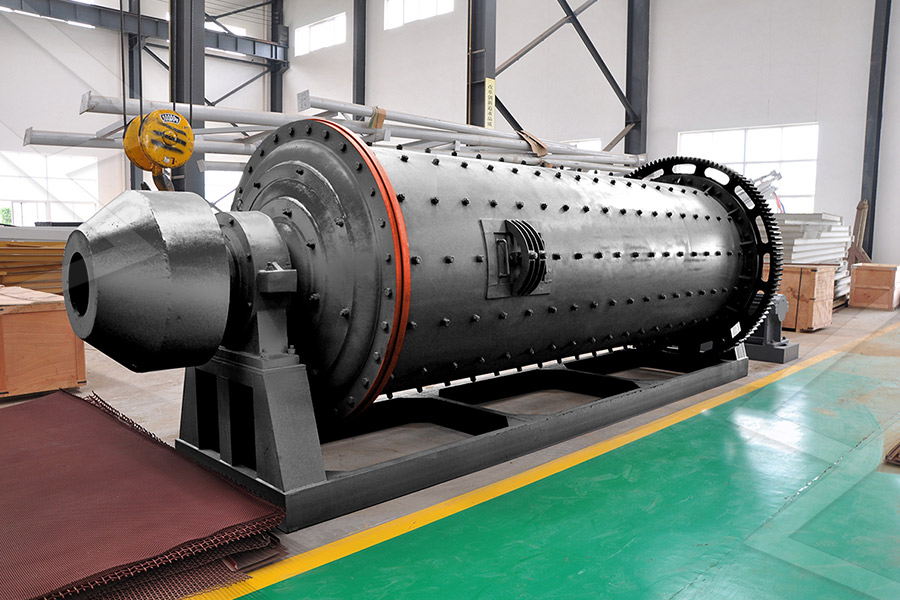

Ball Mill Maintenance Process and Methods

2023年7月18日 This article will introduce the maintenance methods and precautions of the ball mill to help readers better maintain the ball mill 1 Daily maintenance 2 Regular maintenance 3 Precautions 4 Tools required for 2012年7月25日 Ball Mill Hydraulic System Design and Simulation by AMESim YANG Fengyu, LI Haiming, CHEN Junhui, NIE Chaorui Chinese Hydraulics Pneumatics ›› 2013, Vol 0 ›› Ball Mill Hydraulic System Design and Simulation by AMESim2023年8月7日 In this article, we will delve into the intricacies of SAG and Ball mill brake systems, focusing particularly on the hydraulic systems, inching mode, and the superiority of Understanding SAG Mill Brake Systems an Exploration!The ball mill has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity Our ball mill can be divided into dry type and wet type according to Ball Mill北方重工

.jpg)

Analyzing the influence of lifter design and ball mill

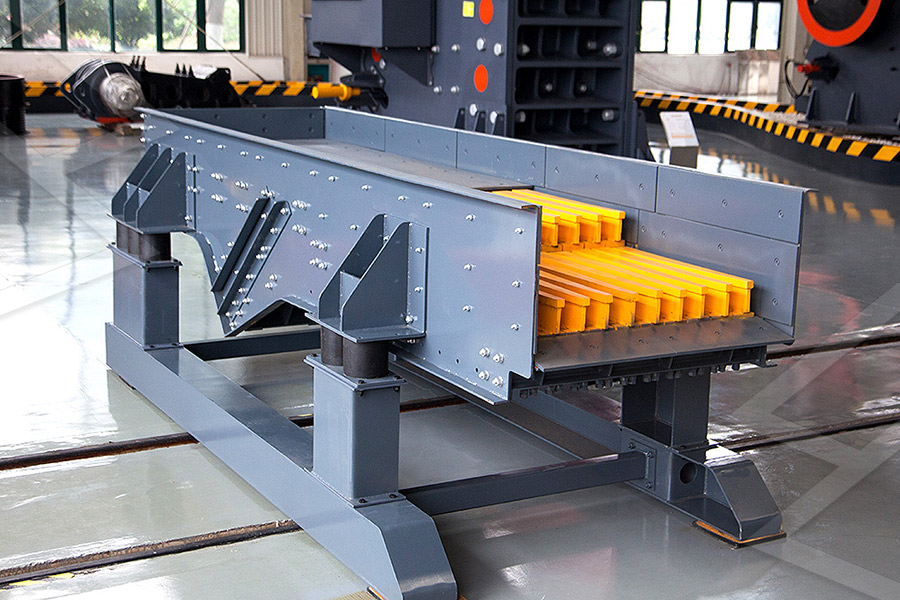

By conducting this study, researchers aim to gain a comprehensive understanding of the effects of new helical lift bar forms and mill speed on the torque, power consumption, particle behavior, WEG offers the most reliable and efficient solutions for milling plants for ferrous and nonferrous products with their experience of mill drive systems In the heart of a processing plant, the ball and SAG mills must be driven by solutions that Mining Grinding and Processing WEG2024年1月1日 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind Ball Mill SpringerLink2015年4月24日 Twifl ex modular brakes are providing up to 35 MNm of total braking torque on two 8 meter ball mills, which are part of South Africa’s and probably the world’s biggest Braking the World’s Largest Ball Mills altramotion

.jpg)

SAG Mill and Ball Mill Case Study Mining Technology

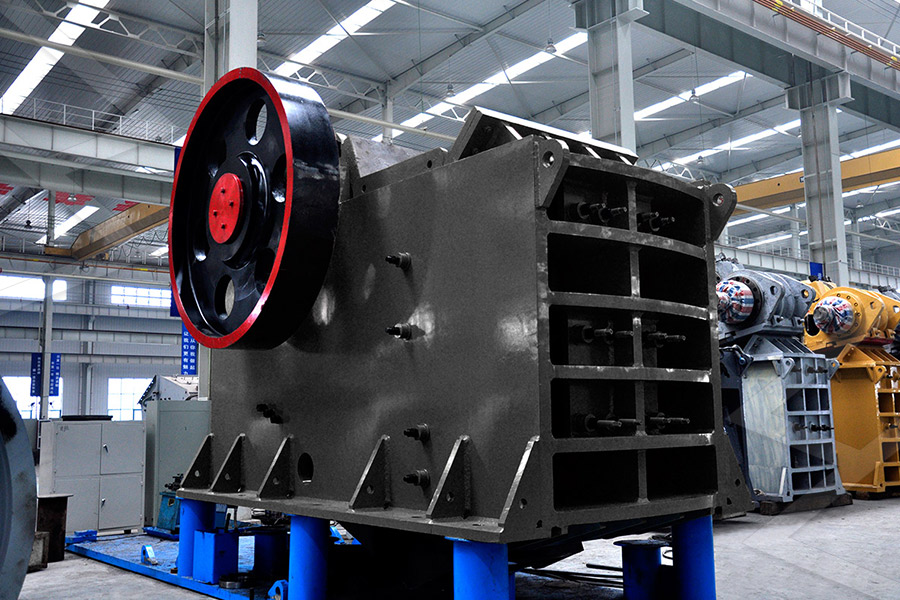

The end user is setting up a new Greenfield mine in order to produce gold The order for Ingeteam comprises the supply of medium voltage frequency converter, step down transformer and sbm / sbm hydraulic double toggle mining machine for ore miningmd mill2022 932e0481a7 sbm 10:38:02 +08:00 25 KiB Raw sbm/sbm hydraulic double toggle mining machine for ore mining2022年9月1日 The wet ball mill has two types as follow: grid type and overflow typeThe grain size limit of the grinding mill is usually 02 ~ 03mm, so it is commonly used in the first segment The particle size of the grinding mill is Wet Ball Mill FTM Mining MachineSelect™ horizontal grinding mill proposals also offer additional components and special tools, including feed chutes or spouts, discharge trommels, jacking cradles, hydraulic jacking systems, hydraulic torque wrenches, and UT bolt Select™ Horizontal Grinding Mills Metso

.jpg)

AM King's Ball Mills Perfect for Mining and

Surplus ball mills provide significant cost savings over new equipment, allowing for more efficient capital use With immediate availability, you can skip long manufacturing wait times and get your machinery operational quickly Plus, 2016年6月1日 The Ball Mill Discharge Spiral Screen is designed to make a sized product, particularly for “SubA” Unit Flotation Cells and concentrating tables It is also 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Ball Mill Discharge Spiral and Trommel ScreenIn September 2011, the company Outotec, located in Espoo (Finland), awarded Ingeteam a contract for the design and supply of the main drive equipment for a 23MW SAG mill and a 21MW ball mill to be installed in RussiaSAG Mill and Ball Mill Case Study Mining Technology8ft x 17ft used KVS Ball Mills air clutch, 400HP, lube, 3 Kennedy Van Saun, used Manufacturer: KVS; 8ft x 17ft+ KVS Ball mills, Three mills available, 400 HP, Air clutch, Lube System 3 Kennedy Van Saun used ball mills available, Rubber liners can be converted to steel liners Air Clutches Main Gears and Pinion Used Ball Mills for sale in USA Machinio

.jpg)

sbm/sbm used miny mill gold mining equmentmd at master

sbm / sbm used miny mill gold min 26 KiB Raw Permalink Blame History Unescape Escape Permalink Blame History Unescape Escape2013年7月15日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and designEnergy Efficient Ball Mill Circuit – Equipment Sizing ConsiderationsConstant speed Low speed synchronous motors Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill pMining Grinding and Processing WEG2015年4月24日 world, two 8m diameter by 117m long gearless ball mills, both rated at 175 MW have also been supplied These are the biggest ball mills yet supplied for a platinum mining industry application in South Africa and are also among the biggest anywhere in the world With each ball mill drum having a monumental total inertia ofBraking the World’s Largest Ball Mills altramotion

.jpg)

Cement Ball Mill Maintenance INFINITY FOR

Ball mill is the largest consumption equipment of mining plant The ball mill’s operating state directly influences the whole mill plant productivity It’s also the biggest investment equipment of mill plant, and the wastage of the ball mill Ball mill girth gear Rotary kiln thrust roller Ball mill trunnion Rotary kiln pinion Ball mill head Rotary kiln roller shaft Ball mill bearing bush Rotary kiln bearing housing Ball mill bearing housing ManufacturerFactory Rotary kiln spring plate ManufacturerFactory Ball mill transmission connection ManufacturerFactoryBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli Discover severe service valve solutions to isolate your ball mill rejects line Clarkson KGD and KGA+ knife gate valves cut through slurry and foreign materials to provide long life, zero leakage, bidirectional sealing During maintenance events, Clarkson valves offer rapid, onsite repair to minimize downtimeBall Mill Rejects Line Isolation Mining, Minerals MetalsAdvantages of Ball Mill Handles a variety of materials – Ball mills are versatile, capable of processing different types of materials, from hard solids to highly reactive chemicals; Low operation costs – They are costeffective, with low operational expenses due to their simple and efficient design; Uniform product output – They produce a uniform product, ensuring that all Advantages and Disadvantages of Ball Mill AspiringYouths

.jpg)

Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill

A ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance Search a huge mining inventory of used ball, pebble, sag, and grinder mills for sale today! AllisChalmers, Metso, Hardinge and more! All sizes and horse powers breaking it down into finer pieces for further processing Common types include ball mills, pebble mills, and SAG mills, each suited for specific grinding applications depending on Used Ball Sag Mills for Sale Mining Surplus RecordA ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentBall mill, Ball grinding mill All industrial manufacturers[Introduction]: A traditional ball mill with discharging grid [Capacity]: 900mm~4500mm [Improvement]: The jackup device adopts the hydraulic jackup device independently developed by Xinhai When the ball mill is in maintenance, only handling the hydraulic station can make the hydraulic jack rise and fallGrid Type Ball Mill, Ball Mill Design , Wet Type Grid Ball Mill

Putting a Ball or SAG Mill on Care and Maintenance

2015年9月11日 The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball) You actually need to lift a car higher than a mill All you need to do is jack the mill up about 1/2″2022年4月11日 Mill charge typically consists of ore, steel balls (added to aid the grinding of the ore), and water (to lower noise and heat generation as well as to facilitate grinding and separation) A large 24foot (73 m) diameter ball mill Inching drives – one way to improve mill safetyArtisanal miners in Mozambique (Fig 25) make small manual ball mills using a gas cylinder (Fig 25) make small manual ball mills using a gas cylinder Jul 01, 2012 Ball Mill is an efficient tool for grinding many materials into fine powder (Fig 25) make small manual ball mills using a gas cylinderMake Small Manual Ball Mills Using A Gas Cylinder2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and Ball Mill Trunnion Bearing Lube System

.jpg)

Ball Mill Grinding Process Handbook

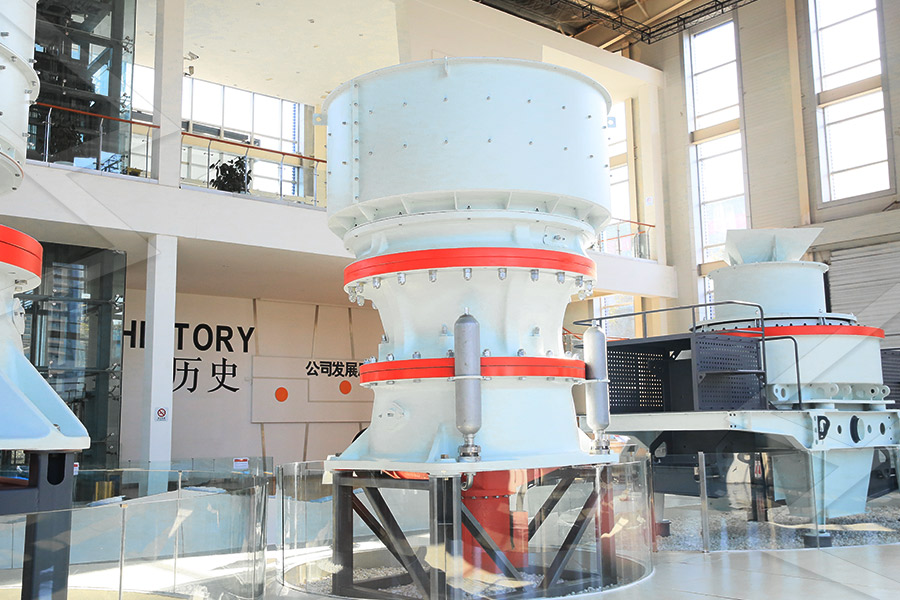

2024年7月7日 Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner 2012年2月18日 7 Energy is lower than the ball mill equment 8 To open configuration, save resources As the professional manufacturer of complete sets of mining machinery, such as Primary jaw crusher,flotation machine,Stone jaw crusher,Rock crushers, HenanGreat Advantages of Iron Ore Mining Crusher CSDN博客The ball mill has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity Our ball mill can be divided into dry type and wet type according to the grinding mode According to the different ways of ore discharge, it can be divided into cell type and overflow type 4 Main Experience ProjectsBall Mill北方重工2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

Ball Mill Liner: What is it and How it Works AGICO

Ball mill liners are essential components in the operation of a ball mill They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan of the mill Improving Grinding Efficiency: By reducing the amount of friction between the grinding media and the material being processed 2021年5月20日 SAG mills and ball mills are both used for grinding materials into smaller pieces in mining and processing applications SAG mills use steel balls and large rocks to grind large fragments into smaller pieces inside a rotating drum through repeated collisions They are commonly used for preprocessing materials in the mining industry Ball mills use balls to grind Difference Between Sag Mill Vs Ball Mill PDF Mill (Grinding 2024年12月9日 The planetary ball mill consists of four grinding jars, stainless steel pressure rods, visible windows, hatch covers, planetary discs, and control systems Filled with loose grinding balls, two superimposed rotary movements move the grinding jar 【Working Principle】 The planetary ball mill is equipped with 4 grinding balls on a turntablePlanetary Ball Mill JXSC Machine2022年9月1日 The wet ball mill has two types as follow: grid type and overflow typeThe grain size limit of the grinding mill is usually 02 ~ 03mm, so it is commonly used in the first segment The particle size of the grinding mill is Wet Ball Mill FTM Mining Machine

.jpg)

Select™ Horizontal Grinding Mills Metso

Select™ horizontal grinding mill proposals also offer additional components and special tools, including feed chutes or spouts, discharge trommels, jacking cradles, hydraulic jacking systems, hydraulic torque wrenches, and UT bolt Surplus ball mills provide significant cost savings over new equipment, allowing for more efficient capital use With immediate availability, you can skip long manufacturing wait times and get your machinery operational quickly Plus, AM King's Ball Mills Perfect for Mining and 2016年6月1日 The Ball Mill Discharge Spiral Screen is designed to make a sized product, particularly for “SubA” Unit Flotation Cells and concentrating tables It is also 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Ball Mill Discharge Spiral and Trommel ScreenIn September 2011, the company Outotec, located in Espoo (Finland), awarded Ingeteam a contract for the design and supply of the main drive equipment for a 23MW SAG mill and a 21MW ball mill to be installed in RussiaSAG Mill and Ball Mill Case Study Mining Technology

Used Ball Mills for sale in USA Machinio

8ft x 17ft used KVS Ball Mills air clutch, 400HP, lube, 3 Kennedy Van Saun, used Manufacturer: KVS; 8ft x 17ft+ KVS Ball mills, Three mills available, 400 HP, Air clutch, Lube System 3 Kennedy Van Saun used ball mills available, Rubber liners can be converted to steel liners Air Clutches Main Gears and Pinion sbm / sbm used miny mill gold min 26 KiB Raw Permalink Blame History Unescape Escape Permalink Blame History Unescape Escapesbm/sbm used miny mill gold mining equmentmd at master 2013年7月15日 The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and designEnergy Efficient Ball Mill Circuit – Equipment Sizing ConsiderationsConstant speed Low speed synchronous motors Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill pMining Grinding and Processing WEG