Beneficiation Concentrating Iron Ore

An overview of the beneficiation of iron ores via reverse

2014年3月10日 Research regarding iron ore flotation began in 1931, demonstrating that reverse cationic flotation is a very efficient method for beneficiating oxidised iron ores This method 2023年11月20日 The combination of classic and new techniques such as molecular modeling and the application of ultrasound as a dispersion method can help to improve the efficiency of Exploring the Challenges and Advances in Concentrating Ultrafine Iron 2014年3月1日 Research regarding iron ore flotation began in 1931, demonstrating that reverse cationic flotation is a very efficient method for beneficiating oxidised iron ores This method can also be(PDF) An overview of the beneficiation of iron 2023年1月1日 This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current operating Iron ore beneficiation: an overview ScienceDirect

.jpg)

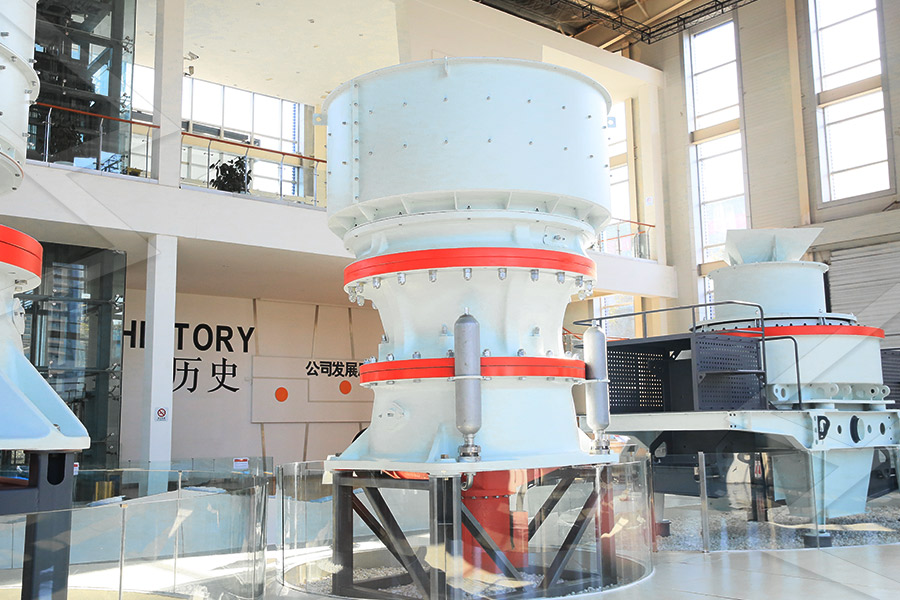

Beneficiation Plants and Pelletizing Plants for Utilizing

2015年1月27日 Presently, the most effective and often followed route taken to utilize such deposits is the provision of beneficiation plants for upgrading iron ore and pelletizing plants for 2019年12月17日 Reduction roasting is one of the most efficient techniques for upgradation of the iron content in typically complex lowgrade iron ores The method involves the(PDF) Beneficiation of Complex Banded Iron 2014年12月22日 The problems of the iron ore raw materials beneficiation process automation with a justification of method of prevailing technological variety operational definition in ore Automation of iron ore raw materials beneficiation with 2023年1月1日 Increasing the integrated use of iron ore raw materials is associated with an increase in the yield of iron concentrate and the production of hematite concentrate during the Iron ore beneficiation: an overview ResearchGate

.jpg)

A critical review on metallurgical recovery of iron from iron ore

2024年4月1日 Iron ore tailings (IOTs) are byproducts generated during the beneficiation process of iron mining, encompassing stages such as gravity separation, magnetic separation, 2022年10月27日 Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few tenths of a millimeter in size is not separated as Beneficiation of Magnetically Separated Iron 2014年3月10日 Iron is one of the most common elements in Earth's crust The primary industrial types of ironbearing minerals include oxides and hydroxides and, to a lesser extent, carbonates: magnetite [Fe 3 O 4], hematite [Fe 2 O 3], goethite [FeO(OH)], limonite [FeO(OH) × nH 2 O] and siderite [FeCO 3]The genesis of iron ore deposits is variable, similar to numerous other ore An overview of the beneficiation of iron ores via reverse 2018年8月15日 The strong reducing atmosphere is prone to reducing the Fe 2 O 3, and the reduced iron suboxides are easy to react with vanadium oxide to form the stable spinel phase Fe 2 VO 4 Therefore, the strong reducing atmosphere is more favorable for the beneficiation of vanadium in stone coal 43 Effect of the quantity of Fe 2 O 3 on the A novel approach for preconcentrating vanadium from stone coal ore

A short review on environmental impacts and application of iron ore

2022年1月1日 Increased mining activity of iron ore has led to the generation of voluminous wastes of various nature, especially during the different stages of its extraction and production The improper disposal of such waste causes negative impact on the environment One such waste which is generated during the beneficiation process of iron ore is waste iron ore tailings, 2019年1月15日 Other recently commissioned lithium mines in Australia concentrating spodumene from hard rocks include Bald Hill, Mt Cattlin and Mt Marion Zinnwaldite is considered as an impure variety of lepidolite with relatively high iron content (up to 115% Fe as FeO) and MnO (32%) In many lithium ore beneficiation plants, it is a common The beneficiation of lithium minerals from hard rock ores: A 2024年7月30日 2 Iron Ore Iron is the most abundant element on earth by mass Hematite (𝐹𝑒2O3) and magnetite (𝐹𝑒2O3) are the most common iron ores found in nature Iron Ore deposits are found in sedimentary rock Gangue refers to the unwanted minerals It includes silica (SiO2), alumina (Al2O3), Phosphorus: These gangue materials are crucial considerations in iron ore Iron Ore Benification process Presentationpptx SlideShare2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring Beneficiation of Iron Ore 911Metallurgist

.jpg)

Exploring the Challenges and Advances in Concentrating Ultrafine Iron

2023年11月20日 This paper was supported by Vale SA in the context of developing new beneficiation routes for iron ore The support of LABMOL/CETEM (Centre for Mineral Technology) is also acknowledged The support of GeoRessources Laboratory, University of Lorraine, is greatly acknowledged2018年8月25日 A Beneficiation Study on a Low Grade Iron Ore by Gravity and Magnetic Separation1 Hossein Akbaria, *, Mohammad Noaparasta, Sied Ziaedin Shafaeia, [11, 12] It also remains the main concentrating method for iron and tungsten ores and is used extensively for treating tin ores, coal and many industrial minerals [11] The multi gravity A Beneficiation Study on a Low Grade Iron Ore by 2024年2月7日 Flotation is widely used as the primary beneficiation technique for nonmagnetic iron ores, and is often used for further for concentrating iron ore In reverse flotation the goal is toFlotation of Iron Ores: A Review ResearchGate2023年3月13日 The highgrade copper concentrate can be obtained by the coarse grinding, roughing, scavenging of copper ore, then grinding and concentrating of coarse concentrate Classification of copper ore Almost all How to Process Copper Ore: Beneficiation

Beneficiation In Mining: Transforming Iron Ore For A

2024年12月7日 Beneficiation has become a cornerstone of modern mining, particularly in the iron and steel industry This critical process involves improving the quality of raw iron ore by removing impurities 2024年4月26日 Grinding and beneficiation are crucial steps in iron ore processing as they enhance the concentration of ironbearing minerals and remove impurities These processes contribute to improving the overall quality and value of the ore, making it suitable for various downstream applications, including steelmaking Continuous advancements in grinding Iron Ore Processing: From Extraction to Manufacturing2021年5月20日 The potential iron loss in ore beneficiation of three hypothetical ores with a rich fraction consisting of haematite containing 1% Si and 67% Fe and having a fraction consisting of 70% SiO 2 and 10%, 15% and 20% Fe In this calculation, the poor fraction is discarded and the iron loss is presented per ton of DRpellet feedDriving investments in ore beneficiation and scrap upgrading 2023年12月21日 Overview of the beneficiation process used by the Yuanjiacun iron ore concentrator, utilizing anionic reverse flotation (based on Chen, Ge and Yu 2005; Mao, Huang and Zhao 2005)Overview of the beneficiation process used by the Yuanjiacun iron ore

.jpg)

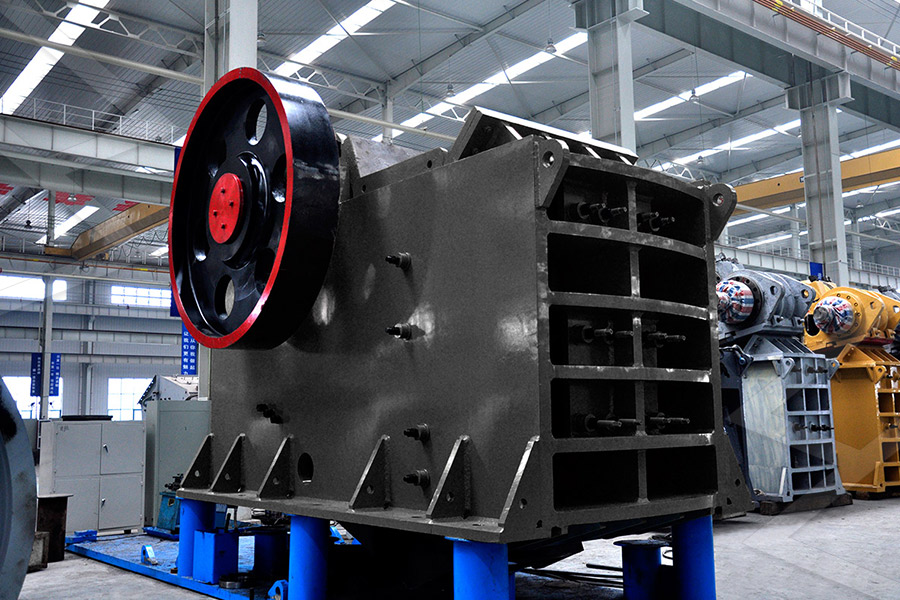

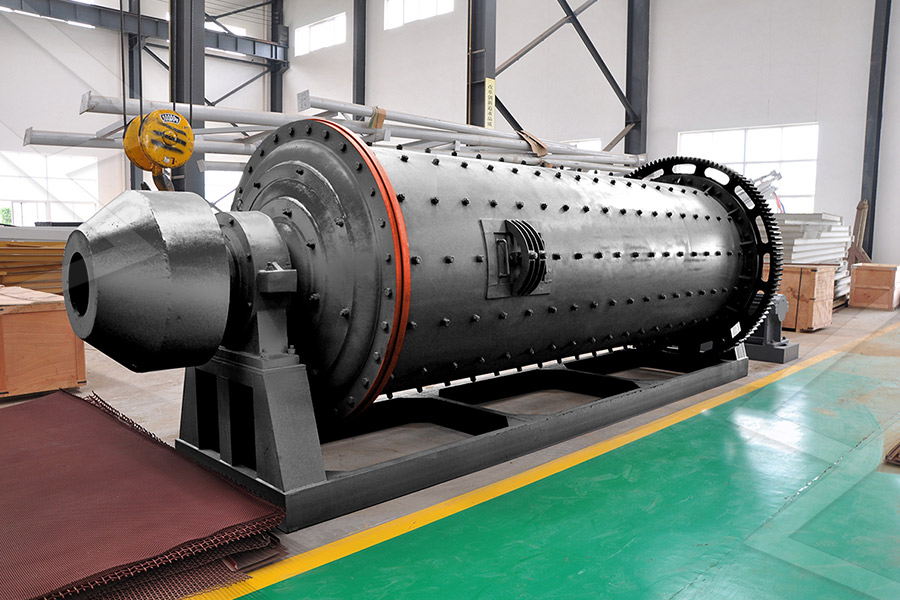

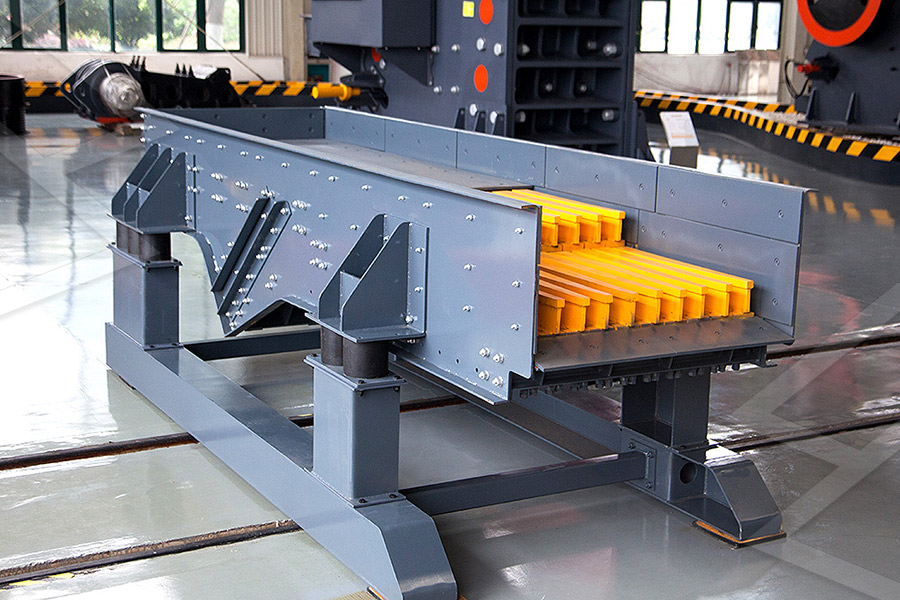

Comminution and classification technologies of iron ore

2022年1月1日 Additionally, iron ore processing facilities often receive ores from various sources (such as satellite pits) with different qualities These ores may be treated by different processing routes and/or blended to meet product specifications Some examples of different iron ore crushing and screening flowsheets are provided below:2023年2月15日 Coarsegrained hematite refers to iron ore with an embedded particle size of 2mm or more It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to How to Extract Iron from Hematite: Methods and Plants2013年1月1日 Magnetic separation is a simple, inexpensive, nondestructive and rapid means of concentrating ironbearing minerals to nearly monomineralic levels, particularly those present in different proportions in clays The use of variable magnetic flux density further allows subfractionation of the ironbearing minerals [17] The selection of magnetic Magnetic separation studies for a low grade siliceous iron ore sample 2021年10月1日 Solarthermal beneficiation of iron ore: Systemlevel dynamic simulation and technoeconomic optimisation 2023, Applied Thermal Engineering Show abstract Use of solar energy through concentrating solar power (CSP) systems is widely investigated in current literature CSP systems rely on focusing and concentration of solar energy onto a Evaluation of concentrated solar thermal energy for iron ore

.jpg)

Evaluation of sampling systems in iron ore concentrating and

2018年1月15日 Application of variographic analysis to process data in LKAB iron ore concentrating and pelletizing enabled characterization of sampling systems through the entire value chain (not all sampling system evaluations are shown here) Sampling and analysis variability components were quantified and opportunities for possible improvements of 2018年9月17日 3 Introduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore Iron steel is the driving force behind industrial development in any country The mining of iron ore, an Seminar on iron ore beneficiation in india PPT2018年9月25日 Processes based on the gravity separation technique are extensively being used in iron ore beneficiation because of their lowcost, ease of operation, and ecofriendly nature and is more related to particle density Low grade Iron Ore Beneficiation and the 2015年1月27日 1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low gradeBeneficiation Plants and Pelletizing Plants for Utilizing

.jpg)

(PDF) A Method of Ore Blending Based on the Quality of Beneficiation

2021年5月31日 The benefits of ore blending are extending the ore reserve base by utilization of lowgrade, minimizing the need for selective mining hence reducing mining costs and increasing mine production A current trend amongst producers is the increase in dewatering of iron ore fines (05 mm), due to an increase in wet beneficiation processes used to upgrade lower quality ore deposits, increased water content in orebodies located below the water table, and increasing focus on transportable moisture limits (tml) vacuum filtration is commonly used for dewatering of iron ore fines, and The use of filter aids on iron ore fines AusIMM2024年2月14日 A laboratoryscale REFLUX™ Concentrating Classifier was operated in continuous mode to beneficiate a sub 0100 mm tantalum ore with a head grade of 056 wt% Ta The unit incorporated a lower section with a reduced diameter to accommodate a low yield At a yield to underflow product of 40 wt%, a product grade of 133 wt% was achieved (237 Beneficiation of HighDensity Tantalum Ore in the REFLUX™ Concentrating 2012年1月2日 With the depleting reserves of highgrade iron ore in the world, various beneficiation methods have been employed to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand In the iron ore industry, froth flotation is either used as a primary method for concentrating iron ores, such as ClevelandCliffs Froth Flotation of Iron Ores articlesapub

%3C1PGHL[2}HK_]YT.jpg)

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and 2019年2月1日 1 Observation of Iron Ore Beneficiation within a Spiral Concentrator by Positron Emission Particle Tracking of Large (Ø≈1440 μm) and Small (Ø≈58 μm) Hematite and Quartz Tracers D Boucher a*, Z Deng , T Leadbeaterb, R Langlois , KWatersa aDepartment of Mining and Materials Engineering, McGill University, 3610 University Street, Montreal, Quebec, H3A Observation of Iron Ore Beneficiation within a Spiral 2022年10月27日 Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few tenths of a millimeter in size is not separated as Beneficiation of Magnetically Separated Iron 2014年3月10日 Iron is one of the most common elements in Earth's crust The primary industrial types of ironbearing minerals include oxides and hydroxides and, to a lesser extent, carbonates: magnetite [Fe 3 O 4], hematite [Fe 2 O 3], goethite [FeO(OH)], limonite [FeO(OH) × nH 2 O] and siderite [FeCO 3]The genesis of iron ore deposits is variable, similar to numerous other ore An overview of the beneficiation of iron ores via reverse

A novel approach for preconcentrating vanadium from stone coal ore

2018年8月15日 The strong reducing atmosphere is prone to reducing the Fe 2 O 3, and the reduced iron suboxides are easy to react with vanadium oxide to form the stable spinel phase Fe 2 VO 4 Therefore, the strong reducing atmosphere is more favorable for the beneficiation of vanadium in stone coal 43 Effect of the quantity of Fe 2 O 3 on the 2022年1月1日 Increased mining activity of iron ore has led to the generation of voluminous wastes of various nature, especially during the different stages of its extraction and production The improper disposal of such waste causes negative impact on the environment One such waste which is generated during the beneficiation process of iron ore is waste iron ore tailings, A short review on environmental impacts and application of iron ore 2019年1月15日 Other recently commissioned lithium mines in Australia concentrating spodumene from hard rocks include Bald Hill, Mt Cattlin and Mt Marion Zinnwaldite is considered as an impure variety of lepidolite with relatively high iron content (up to 115% Fe as FeO) and MnO (32%) In many lithium ore beneficiation plants, it is a common The beneficiation of lithium minerals from hard rock ores: A 2024年7月30日 2 Iron Ore Iron is the most abundant element on earth by mass Hematite (𝐹𝑒2O3) and magnetite (𝐹𝑒2O3) are the most common iron ores found in nature Iron Ore deposits are found in sedimentary rock Gangue refers to the unwanted minerals It includes silica (SiO2), alumina (Al2O3), Phosphorus: These gangue materials are crucial considerations in iron ore Iron Ore Benification process Presentationpptx SlideShare

Beneficiation of Iron Ore 911Metallurgist

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring 2023年11月20日 This paper was supported by Vale SA in the context of developing new beneficiation routes for iron ore The support of LABMOL/CETEM (Centre for Mineral Technology) is also acknowledged The support of GeoRessources Laboratory, University of Lorraine, is greatly acknowledgedExploring the Challenges and Advances in Concentrating Ultrafine Iron 2018年8月25日 A Beneficiation Study on a Low Grade Iron Ore by Gravity and Magnetic Separation1 Hossein Akbaria, *, Mohammad Noaparasta, Sied Ziaedin Shafaeia, [11, 12] It also remains the main concentrating method for iron and tungsten ores and is used extensively for treating tin ores, coal and many industrial minerals [11] The multi gravity A Beneficiation Study on a Low Grade Iron Ore by 2024年2月7日 Flotation is widely used as the primary beneficiation technique for nonmagnetic iron ores, and is often used for further for concentrating iron ore In reverse flotation the goal is toFlotation of Iron Ores: A Review ResearchGate