Latest Iron Ore Extraction Process Equment

Iron Ore Processing: From Extraction to

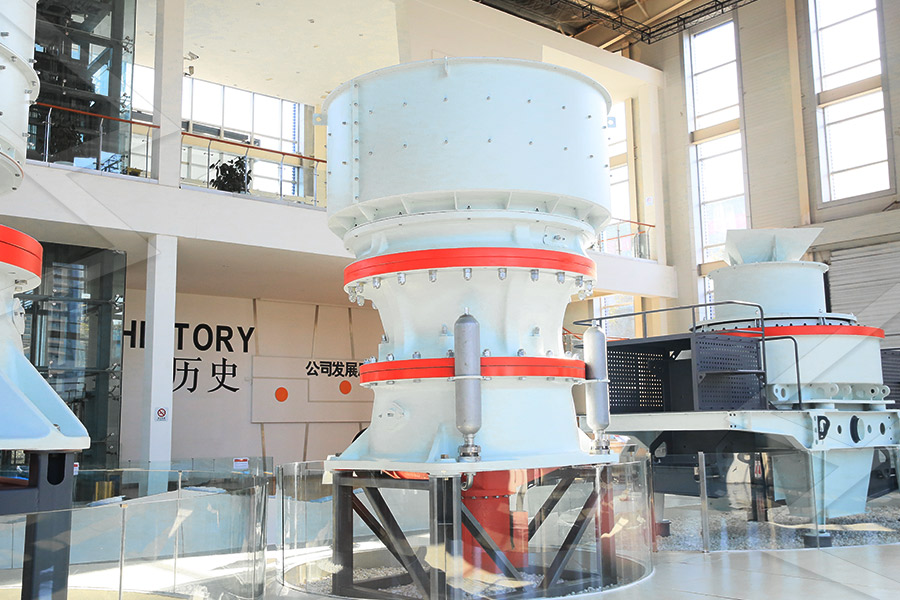

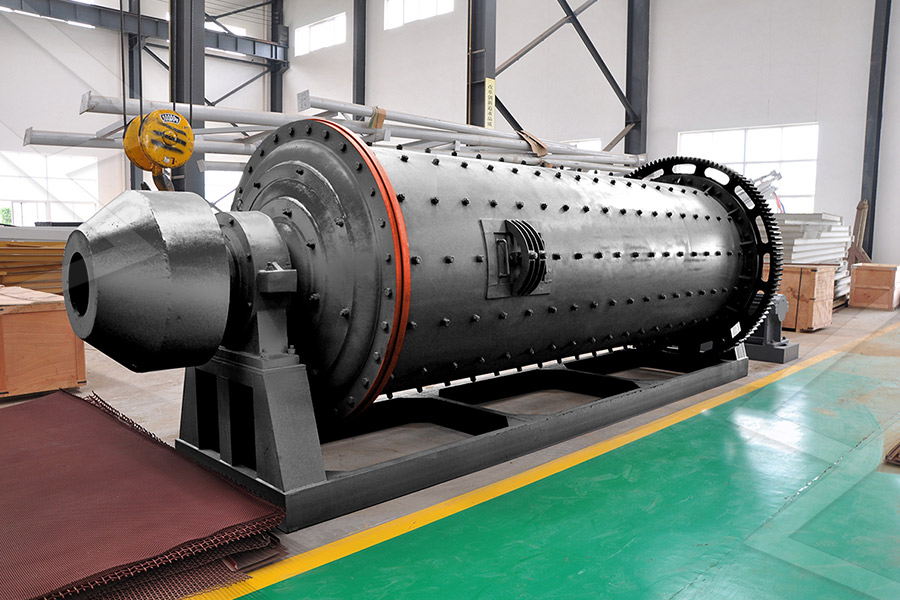

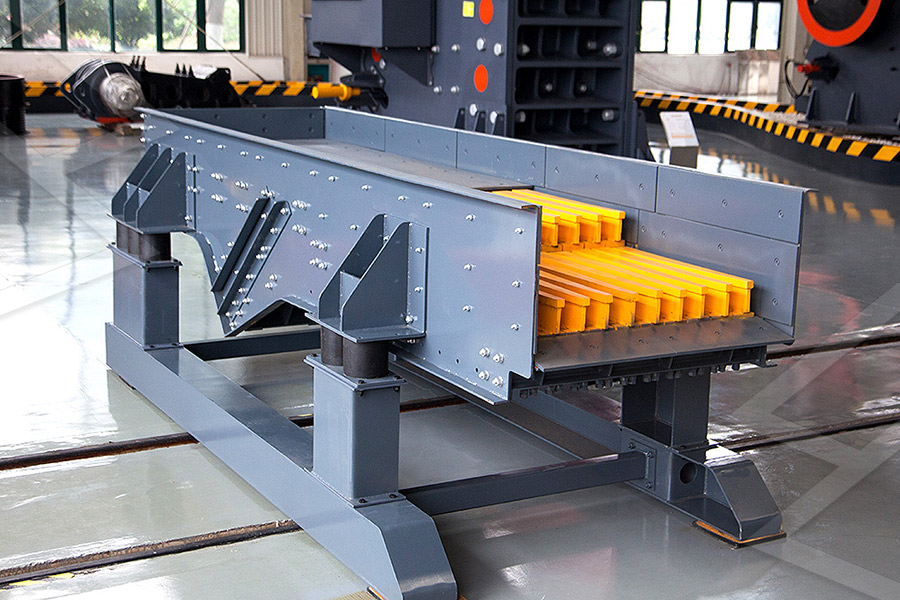

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in 2015年1月1日 These are bedded iron deposits (BID—banded iron formations), channel iron deposits (CID—iron rich fluvial rocks), and detrital iron deposits (DIT—minor alluvial deposits Iron ore extraction techniques ScienceDirect2024年4月14日 This paper introduces different extractants and extraction methods used in iron separation (solvent extraction, ionexchange resin extraction, membrane extraction, and ionic Extraction and separation of iron technology and research 2024年4月19日 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant The particle size The impact of new technologies on the iron ore screening

Exploring LowGrade Iron Ore Beneficiation

2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore reserves, and rising consumer iron and steel demand 2023年12月19日 Coming full circle, iron ore is now mined by equipment made of iron and steel before being sent for export aboard steel ships to countries that make steel products and send them back to the country of originIron Ore Mining Process: From Extraction to Export2024年8月5日 There are several ongoing green steel efforts to mitigate CO 2 emissions from the ironmaking step, where ore is converted to metal All these possible green iron/steel Economics of Electrowinning Iron from Ore for Green Steel 2024年4月14日 This paper introduces different extractants and extraction methods used in iron separation (solvent extraction, ionexchange resin extraction, membrane extraction, and ionic Extraction and separation of iron technology and research

.jpg)

A critical review on metallurgical recovery of iron from iron ore

2024年4月1日 The study showed that under optimal conditions of 97 M HCl and 04 M extractant concentration, the iron extraction rate was 9719% In addition, it is worth noting that 2024年11月17日 The aim of the study is to extract alumina value from iron ore tailing by using flotation and leaching process Alumina can be removed from iron ore tailing using ether amine as a collector and corn starch as depressant through flotation process in alkaline medium ranging from pH 7 to 10Extraction of Alumina Value from Iron Ore Tailing by Using 2024年7月1日 Highsilicon iron ore tailings, typically regarded as a byproduct of iron ore processing, are utilized innovatively in this study for the extraction of 9999% highpurity quartz (HPQ) An innovative process consisting of Wet HighIntensity Magnetic Separation (WHIMS) with refined twostage mixed acid leaching was developedInnovative process for the extraction of 9999% highpurity 2024年10月9日 The mining industry is undergoing a transformative shift driven by the rapid advancement and adoption of automation technologies This paper provides a comprehensive overview of the current state of automation in Equipment and Operations Automation in

Recovery of Metals from Titanium Ore Using Solvent Extraction Process

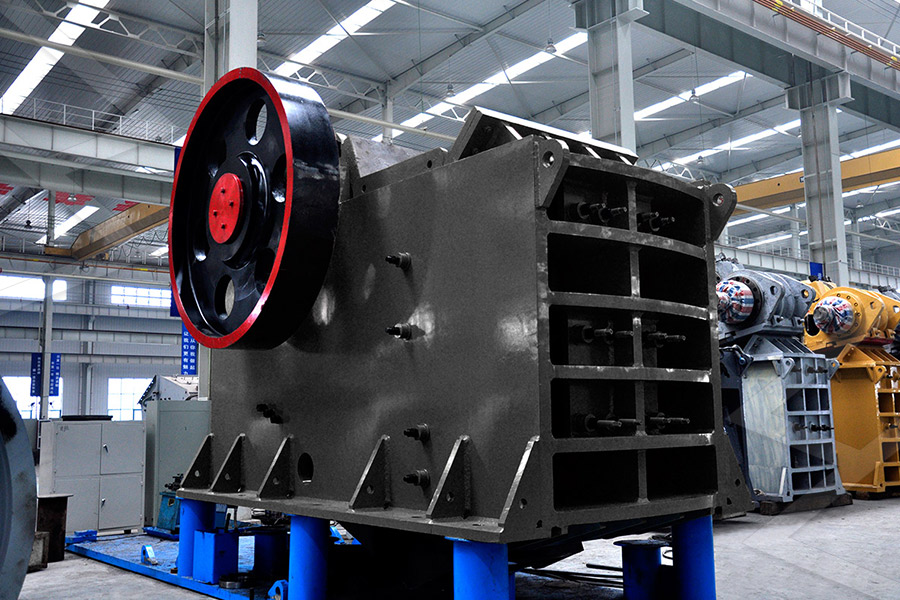

2024年11月28日 Solvent extraction of metals from Ti ore was investigated with a view of enhancing extraction yields by changing the concentration of the ligands, the rate of mixing, the pH, and the temperature of the solution Norwegian Ti ore was leached with 5M HNO3 alongside 10% ascorbic acid to obtain a pregnant solution containing transition metals and some rare 2024年8月27日 The process of refining iron from its ore involves several phases, the most important being the process of putting the iron ore in a form that can easily be used in industries Here’s an overview of the process: Concentration of Ore Mineral iron is extracted and then it goes through a further process in which it is pulped or crushedIron Ore: Extraction Methods, Types Locations Sree 2020年9月23日 This paper presents a review of the classification and extraction methods, as well as general applications of REEs with emphasis on secondary sources such as coal and coal byproducts, iron ore A Review of RareEarth Elements Extraction with Emphasis 5 天之前 This job often falls to jaw crushers because they can manage large batches of a variety of hard, abrasive materials including granite, iron ore, asphalt, glass, and porcelain Jaw crushers work using a moveable die plate (like a person’s lower jaw) to force the material against a stationary plate (like a human upper jaw), squeezing it until Jaw Crusher or Hammer Mill: Which is Right for Your

.jpg)

A critical review on metallurgical recovery of iron from iron ore

2024年4月1日 Fig 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 25–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7]In 2019, the global annual 2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore importing country and imported about Introduction: Overview of the global iron ore industry2015年1月1日 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Life cycle assessment of iron ore mining and processing2023年10月2日 In the dynamic world of mining, Derrick Corporation has become synonymous with innovation W ith a legacy rooted in Australian iron ore processing since the 1950s, Derrick Corporation continues to Revolutionising iron ore processing Australian

Extraction of Iron: Meaning, Purification,

2023年5月14日 The JEE Main Syllabus is out and we figured that Iron Extraction is a very important topic when it comes to Chemistry Keeping that in mind, we are here with a detailed explanation of the concept The extraction of 2011年8月1日 A laboratory experiment was carried out to extract iron from oolitic iron ore by a deep reduction and magnetic separation technique The raw coal with fixed carbon of 66 54% was used as the Iron Extraction From Oolitic Iron Ore by a Deep Reduction Process2024年4月14日 The results show that the extraction rate of trace iron in iron ore slime can reach 9274 % when 08 mL odiazophene and 10 mL ionic liquid were added to the extraction system, the temperature was 80 °C, the pH value was 73 and the extraction time was 30 min Compared with the traditional liquid–liquid extraction method, the extraction Extraction and separation of iron technology and research 2022年12月12日 Transformation and removal behaviors of zinc during the conventional iron ore sintering process Wang, Gan, Fan, Lv, and Ji temperature were achieved by 15 wt% of cokePhase Transformation and Enhanced Zn Removal Technology During the Iron

The Utilization of Bauxite Residue with a CalciteRich Bauxite Ore

2021年3月8日 The Utilization of Bauxite Residue with a CalciteRich Bauxite Ore in the Pedersen Process for Iron and Alumina Extractionpdf Available via license: CC BY 40 Content may be subject to copyrightThe process of extraction of iron from its ore is Register Login Username Password Remember me to Study Start a Free Practice Exam Topic by Topic Video Lessons Past Questions Video Lessons Current JAMB Novel All Novels Latest JAMB Syllabus Latest JAMB Brochure Exam Ranking Ask a Question All Questions SchoolBased The process of extraction of iron from its ore is Myschool2022年1月1日 Iron ore was won by drilling and blasting (Fig 71)As mining technology generally developed, so did drilling techniques and the explosives used Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as “dogger”) allowing mine drivages to be selfsupporting However, he states that in later years where the mining Iron ore extraction techniques ScienceDirect2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (ie goethite, hematite, magnetite, maghemite, siderite, etc) in the past few decades, but the challenges of maintaining the iron and steelmaking processes are enormous The challenges, such as cumbersome production routes, scarcity of Recent Trends in the Technologies of the Direct Reduction

(PDF) Solvent Extraction and Its Applications on Ore Processing

2017年7月3日 To cite this article: YA ElNadi (2017) Solvent Extraction and Its Applications on Ore Processing and Recovery of Metals: Classical Approach, Separation Purification Reviews, 46:3, 195215 2015年12月31日 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter Iron ore extraction techniques Request PDF ResearchGateIron ore processing refers to the techniques used to extract iron from oolitic iron ores, involving processes such as beneficiation, roasting, and magnetic separation to remove impurities like phosphorus and transform minerals for iron and steel production In the process developed by Das and coworkers (2000), the tailings are mixed with Iron Ore Processing an overview ScienceDirect Topics2017年8月28日 The Caron process involves ore drying followed by selective reduction of nickel This is followed by leaching in an ammoniacal solution to bring metals in solution Leaching is followed by precipitation of basic nickel carbonate, which is then decomposed to magnesium chloride containing raffinate from nickel solvent extraction Iron oxide andEXTRACTION OF NICKEL, COBALT AND IRON FROM

.jpg)

Improvement of extracted iron ore grade in underground

2022年1月1日 Decrease in grade and high losses of broken ore are stated to be important problems that accompany the process of marketable production in mining of iron ore deposits by underground methods2023年9月18日 To know more about this process and iron ore mining, contact us and learn all about iron ore, polyurethane, and the associated processes of processing iron ore Stockpiling And Crushing Before being crushed, the iron ore must first be broken up to an F 80 grind sizeTop 6 Steps Of Iron Ore Processing Australian Mining 2011年8月1日 A laboratory experiment was carried out to extract iron from oolitic iron ore by a deep reduction and magnetic separation technique The raw coal with fixed carbon of 6654% was used as the reductant The iron was successfully extracted from the oolitic iron ore which otherwise is nearly impossible to be separated due to its extremely finegrain and mosaic Iron Extraction From Oolitic Iron Ore by a Deep Reduction Process 2023年11月6日 Deposit formation in the coalfired rotary kiln is frequently found in the production of fluxed iron ore pellets by the gratekiln process and affects normal productionDisposal of zinc extraction residues via iron ore sintering process

.jpg)

(PDF) EXTRACTION OF IRON Academia

DETAILS OF EXTRACTION The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore Concentration of ore: In this metallurgical operation, the ore is concentrated by removing impurities like soil etc The process involves the crushing and washing of ore2005年9月30日 Ironbearing seepage from an anaerobic bog in Adams Township, Houghton County, Michigan (long 8861089W, lat 4711854N) This seepage indicated the presence of bacteria capable of both reducing Direct Biohydrometallurgical Extraction of Iron from Ore2013年1月1日 A second requirement is to sequence the ore extraction so that the variability in ore grade is controlled: failure to do so will result either in lowquality ore being marketed, or excessive re (PDF) Planning an Iron Ore Mine: From Exploration Data to 2024年11月17日 The aim of the study is to extract alumina value from iron ore tailing by using flotation and leaching process Alumina can be removed from iron ore tailing using ether amine as a collector and corn starch as depressant through flotation process in alkaline medium ranging from pH 7 to 10Extraction of Alumina Value from Iron Ore Tailing by Using

.jpg)

Innovative process for the extraction of 9999% highpurity

2024年7月1日 Highsilicon iron ore tailings, typically regarded as a byproduct of iron ore processing, are utilized innovatively in this study for the extraction of 9999% highpurity quartz (HPQ) An innovative process consisting of Wet HighIntensity Magnetic Separation (WHIMS) with refined twostage mixed acid leaching was developed2024年10月9日 The mining industry is undergoing a transformative shift driven by the rapid advancement and adoption of automation technologies This paper provides a comprehensive overview of the current state of automation in Equipment and Operations Automation in 2024年11月28日 Solvent extraction of metals from Ti ore was investigated with a view of enhancing extraction yields by changing the concentration of the ligands, the rate of mixing, the pH, and the temperature of the solution Norwegian Ti ore was leached with 5M HNO3 alongside 10% ascorbic acid to obtain a pregnant solution containing transition metals and some rare Recovery of Metals from Titanium Ore Using Solvent Extraction Process 2024年8月27日 The process of refining iron from its ore involves several phases, the most important being the process of putting the iron ore in a form that can easily be used in industries Here’s an overview of the process: Concentration of Ore Mineral iron is extracted and then it goes through a further process in which it is pulped or crushedIron Ore: Extraction Methods, Types Locations Sree

.jpg)

A Review of RareEarth Elements Extraction with Emphasis

2020年9月23日 This paper presents a review of the classification and extraction methods, as well as general applications of REEs with emphasis on secondary sources such as coal and coal byproducts, iron ore 5 天之前 This job often falls to jaw crushers because they can manage large batches of a variety of hard, abrasive materials including granite, iron ore, asphalt, glass, and porcelain Jaw crushers work using a moveable die plate (like a person’s lower jaw) to force the material against a stationary plate (like a human upper jaw), squeezing it until Jaw Crusher or Hammer Mill: Which is Right for Your 2024年4月1日 Fig 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 25–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7]In 2019, the global annual A critical review on metallurgical recovery of iron from iron ore 2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore importing country and imported about Introduction: Overview of the global iron ore industry

Life cycle assessment of iron ore mining and processing

2015年1月1日 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to